Circular Supply Chains - A Step Towards Sustainability

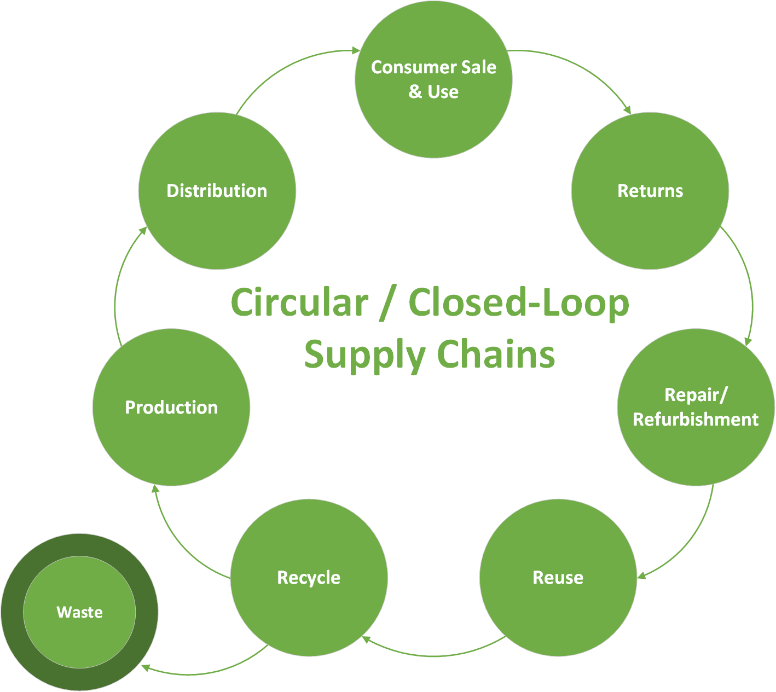

Building upon last week, we are taking a deeper dive into the sustainability movement of circular (a.k.a closed-loop) supply chain practices. The world is moving on from the 'cradle-to-grave' supply chain practice of product manufactured, distributed, used and thrown out. Circular supply chains can be described as the combination of standard logistics and reverse logistics in order to create a circular logistical lifecycle. Products in the reverse logistics flow can be redistributed, repaired for continued use, remanufactured in case of defects, or recycled into parts and materials that have been carefully selected for this purpose. This diagram maps out what a circular supply chain could look like:

Completely closing the loop is an incredibly ambitious goal - zero-waste is no simple task. Significant motivations for circular supply chain economics include the following:

1. Recovered product reduces waste, minimizes direct costs and offers secondary value. Waste reduction is clear - less product heads to landfills when its return is incentivized. Direct costs can be avoided by reusing product as input to production. Finally, secondary value is achieved through sale of recovered outputs on secondary markets.

2. Improved brand-image and customer loyalty. Circular supply chains, and sustainability in general, are mainstream - an outwardly sustainable company earns positive publicity. Returns, repairs, and refurbishment allow for consistent warranty practices that earn customer loyalty and future sales.

3. Product improvement through more data. With more products returning to producer's hands, the entire product lifecycle can be mapped out and defects, usage, and feedback can be utilized to improve product design.

Case Study: IKEA Furniture

In the last 10 years, patience as a consumer has become thin. 'Fast' trends are in - be it 2-day shipping, fast fashion, and even fast furniture. Similar to the way Zara and H&M turned the apparel industry into a race for who could adapt quickly and provide cheap trendy styles, the furniture industry has shifted towards products with a life cycle of 1-2 years. They are low-quality, easy to assemble, and can be left behind when moving residences. IKEA was at the forefront of this trend, and has made significant investment to shift their narrative and lead sustainability initiatives in the furniture industry.

IKEA has explored a multitude of strategies to push towards their goal to be 100% circular using only renewable and recycled materials. Their solutions range from product leasing to secondary markets to using circular materials that can be remanufactured into new products. While the company recognizes its shortcomings - and is realistically very far from their goal - these are big steps for an industry leader and Fortune 100 company to make. Read more about it here.