Where You Locate Your Distribution Centers Matter More Than You Think

Hakan Andersson discusses the topic—where you locate your distribution centers (DCs) matter more than you think. It is a topic that Hakan believes is about the fundamentals in supply chain management. The reason is that this is where you have the chance to really make things good and to change things from the bottom up.

Hello, Dustin, thank you very much for having me here today. Today’s topic—where you locate your DCs matter more than you think—is a topic that I think is about the fundamentals in supply chain management. The reason is that this is where you have the chance to really make things good and to change things from the bottom up.

On a personal note, being a supply chain consultant is a very rewarding job. You get to see a lot, you get to learn a lot, it is very hands-on, and is something that you can understand.

When it comes to supply chain or distribution, network optimization, you are providing the structure for making things right from the start instead of just improving what has been laid out before.

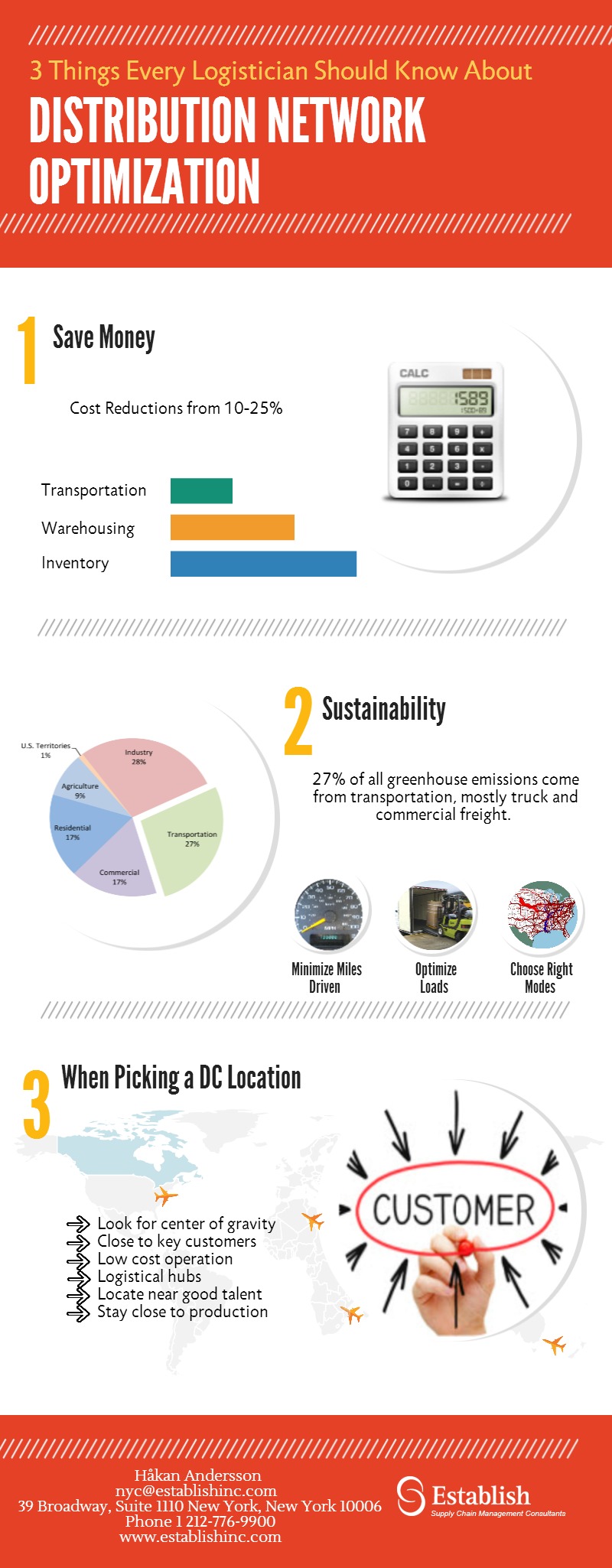

I’ve done this so many times now, and I know that it does save a lot of money. Typically, we would see cost reductions of somewhere between 10 to 25% That is really great. Normally, when you get new transportation routes, you would save an additional 10 to 15 percent in the negotiation phase with the carriers.

You would typically see the cost reductions in transportation, warehousing, and inventory carrying. When it comes to transportation, it’s kind of obvious that what you want to do is to minimize the number of miles that you have to drive and the number of shipments so that you get the most cost-efficient mode and a cost-efficient way of handling it.

When it comes to warehousing, you would consolidate into the most efficient-located and the most efficient location salary-wise, incentive-wise, and real estate cost and everything taken into account. If you do this in the correct way, you would get a better service level with a lower inventory. You would have a win-win situation where, per low cost, you would get a better service.

All of this is great, and those are the reasons why almost all route companies are doing this. But there are other benefits that, to me personally, are more valuable. They very rarely show up in business cases, and very rarely are they a part of the recent way of doing this, and I think that’s a shame. I would get back to that.

The second thing is that when you are doing the network optimization, you have to fight a lot of rational and irrational obstruction and behavior. If we start with the positive side of this, we did establish that you would save a lot of money and reduce cost and you would reduce cost that would directly impact the bottom line, because most of the logistics cost that we’re affecting here are money right out of the company. It’s external invoices that we’re paying or paying less of in the future setup.

When I look at the other benefits—environment, the greenhouse emissions, that’s a huge thing, and we all try to do what we can to—ride fuel-efficient cars, hybrids, we would do recycling our stuff—but we know that according to EPA, 27% of all the greenhouse emissions in the U.S.A., they’re coming from transportation.

Most of transportation is truck, commercial freight, and that is what we’re dealing with as supply chain logistics experts.

If we can set up a structure that minimizes the miles you have to drive the trucks and when the trucks are driving those miles, you can make sure that they are full so they’re not wasting any space and you can make sure that you have the right modes—you’re not flying something that could go on a truck or you’re not trucking anything that can go in water—you have reductions in greenhouse emissions that are far, far greater than what you can do on a personal level.

This is something that very few pay attention to, but this is an area where the logisticians are the heroes.

We know that if we set up a good and well-balanced distribution structure, we know that the accessibility of the stuff that the customer wants, that goes up, which means that if somebody orders something, we can deliver it, and that has a huge impact on whether the customer will return to you.

The way you set it up could also trigger a quicker response and a shorter delivery time.

The struggle that you would have is sometimes caused by very rational reasons, like if you’re afraid of losing your job because this is a more efficient structure; that is a very rational thing to be skeptical of and you will resist change. Or if you would have to move because there is another location that’s more attractive from a logistics standpoint; it’s not an easy thing to uproot your kids and family. Then you have the risk of being outsourced. These are things that we need to be very aware of and to take into account and respect.

The most frustrating is when you see obstructions for other reasons, like there are personal benefits from very long relationships with carriers or other suppliers or there are established truths—“things have always been handled this way” and “we’ve always been in this location; we can’t change,” or when it’s just down to personal comfort that you’ve been dealing with a company for a hundred years and it’s just easy.

I see a lot of this; that’s the darkside of the logistics industry. The way to overcome this is that we try to get people on board that are affected as soon as possible. We also see that younger persons, in general, have a more holistic view on things, and they can see the environmental, the service aspects, and can embrace change in a way that we elders don’t have. And when we have functions outside the supply chain, it also helps a lot.

When it comes to picking the locations, there are so many different aspects to it and there are so many different ways of looking at it, which makes it the more interesting if you’re into logistics and supply chain.

The obvious and most scientific ways to look for is center gravity, which means which location would minimize the number of miles that you have to travel. Typically, if you do that in a consumer industry, you would land somewhere west of Pennsylvania, east of Ohio, that area.

When you have two points, you would typically get one in the northeastern U.S. and one DC in California, Texas, somewhere there. And then you add, if you’re going to have three DCs, somewhere in the Midwest, like Chicago. Then comes somewhere southeast—Georgia. And last, northwest, up in Oregon. We call them the Usual Suspect Five.

There are other strategies that you could embrace here, and center gravity often is just a starting point. You could choose to be close to key customers. The most obvious thing here is if you’re in the auto industry, a supplier to the car makers, you want to be close to where they have their plants.

Dell has taken that to its extreme that you have to have a DC practically on their premises. If you look at Amazon, they are now attacking the cities and having shorter delivery times to the cities, same-day deliveries; and then you need to have the locations close to the cities.

The third approach here is to go for a low-cost operation, where you pick more rural, high-unemployment areas. You would have lower compensation levels, you would have lower cost for real estate, there would be local county/state incentives to establish your operations there; it could be tax reasons.

The fourth and, I would say, very important strategy would be to establish yourself where you have logistical hubs, and this could either be where the carriers would have—you can see at Memphis Tennessee, Louisville, Kentucky; you would see other places where you have a lot of 3PLs.

The reason why we do this is that you would want to be close to a lot of options so that you can change if you’re outsourcing your warehouse. A strategy that is not used often enough I would say is a place that is attractive for your employees to win the war for talent and get really hotshots to join your company.

Then I would say the last strategy and probably the most used is that you stay close to where you have a production facility. This is a knee jerk reaction and an intuitively right way of doing it. It very often pays off to instead be close to where you have your end customers, because from your production side, you can very often efficient transportation, the first leg and then position yourselves where you can have a quick response to your clients, to your customers, and where you can get good reaction time.

I do want to say to finish this up that there is so much more to say about the network optimization, distribution supply chain network both inbound and outbound, but don’t forget that it’s more than a better cost: environmental reasons; the benefits from a service point of view are huge. Thank you very much.